RJ Watson’s Key Role in Westshore Terminals’ $800 Million Upgrade for Global Potash Export

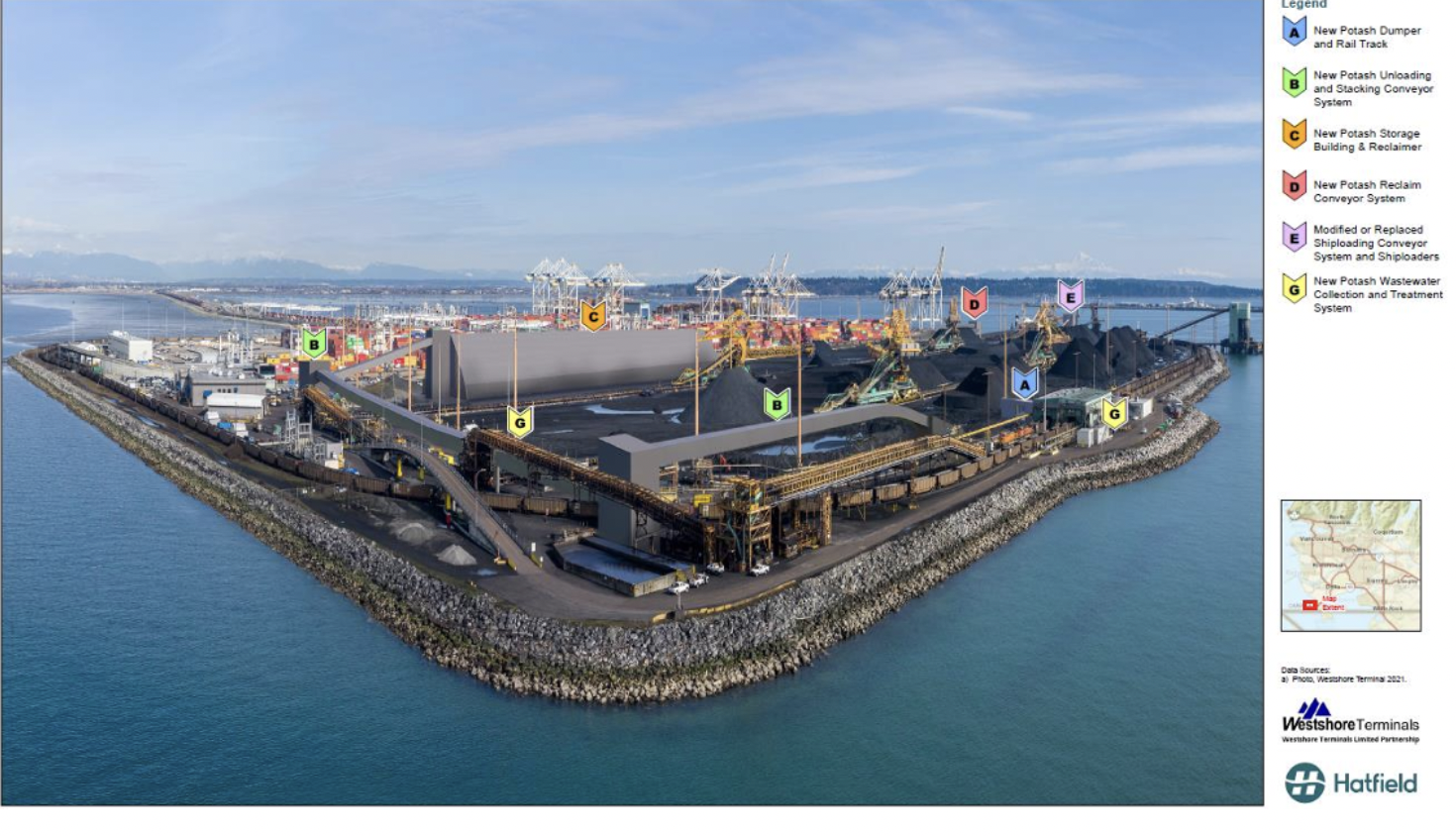

RJ Watson is thrilled to have been selected as the bearing provider for the ambitious $800 million upgrade of Westshore Terminals in British Columbia, a project that underscores our role in facilitating the global export of potash. Westshore Terminals, a key player in North America’s export infrastructure, is located at the Port of Vancouver. It specializes in processing and shipping raw materials from British Columbia and Alberta to international markets.

Potash, a crucial agricultural nutrient, plays an essential role in enhancing crop yield and soil fertility. With the global demand for this vital mineral escalating, the need for efficient transportation and handling systems at port terminals has never been more critical.

In partnership with CWA Engineers and Jacobs Engineering, RJ Watson is in the preliminary stages of designing and preparing to supply 38 structural bearings for the potash conveyor systems at this port terminal. This project marks a significant shift from our standard transportation bridge endeavors, highlighting our ability to adapt and innovate. The project is distinguished by its scale and the variety in the design of the bearings, featuring 17 different types. Notably, one of these bearings is designed for an unprecedented 11 feet of displacement, a requirement that far exceeds the typical movement seen in most highway bridge bearings and involves a slide plate nearly 12 feet in length.

Our involvement in the Westshore Terminals upgrade project not only demonstrates RJ Watson’s capability to push the boundaries of our traditional projects but also emphasizes our commitment to global agriculture and the efficient transportation of essential nutrients like potash. Collaborating with top-tier engineering firms, we are tackling the unique challenges this project presents, continuing to lead the way in structural engineering solutions. Taking on this project in industrial conveyor systems and bearing customization showcases our strong commitment to quality and our contribution towards improving global food security. As we move forward with this work, we’re eager to embrace the many chances it offers to support crucial infrastructure projects worldwide. This project excites us and deepens our resolve to make a meaningful difference globally.