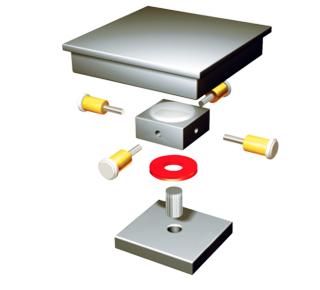

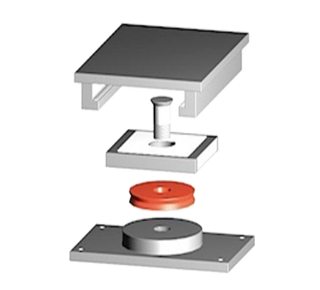

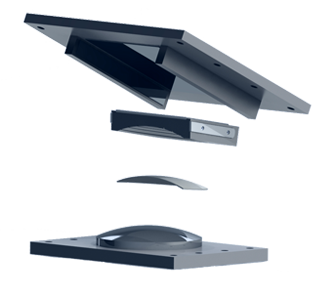

RJ Watson Bearings

RJ Watson designs, manufactures and tests structural bearings for bridges and other civil engineering structures.

High-quality yet cost-effective

RJ Watson’s emphasis is on the utilization of state of the art technology combined with personnel who are renowned for their expertise in this field, specializing in both seismic and non-seismic applications.

RJ Watson Services

The RJ Watson in-house operations include a fabrication shop with overhead cranes, heavy lifting capacities, certified welders, weld positioners, media blasting and machine shop.

When the experts have questions, they turn to

RJ Watson

RJ Watson works with engineers, contractors and owners to create bridges and highways that reliably serve their communities while simultaneously solving engineering challenges. RJ Watson is available to work with you to create a cost effective solution for your specific project.