EQS Sliding Isolation Bearings

Minimize forces and displacements experienced by structures during an earthquake

Seismic Isolation Bearings

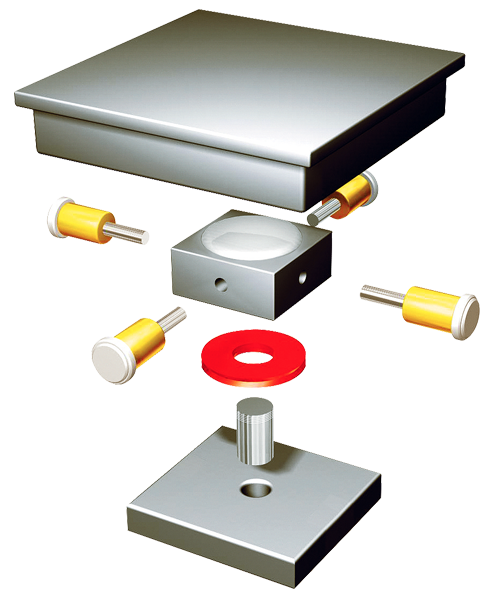

Seismic isolation bearings are one of the most powerful tools in earthquake engineering for isolating a structure and mitigating the most devastating consequences of a seismic event. The EradiQuake System (EQS) from RJ Watson is a state-of-the-art isolation bearing system designed to minimize forces and displacements experienced by bridges and other structures during an earthquake.

EQS

Customizable Isolation Bearings

RJ Watson’s sliding isolation bearings dissipate seismic energy through friction, and each bearing can be designed to achieve a wide variety of energy dissipation levels. This control gives engineers the ability to optimize a structure’s response to seismic events. While originally designed for bridges, the EQS has also been used to mitigate seismic forces on buildings.

Integrity through Simplicity

The EQS protects the integrity of bridges and other structures during seismic events. These isolation bearings are simple to design, install and maintain and can be used to retrofit existing structures.

The RJ Watson system uses readily available materials for an affordable seismic isolation solution and can even reduce the overall cost of a project by reducing forces and displacements.

Design & Test Your Bearings

The experienced engineers at RJ Watson can help you find the right bearings for your project with a no cost, no obligation, design and testing services.

Featured Project

UNASUR Building

Specially modified EQS bearings provided horizontal and vertical isolation and were installed on the UNASUR building in Quito, Ecuador.

When the experts have questions, they turn to

RJ Watson

RJ Watson works with engineers, contractors and owners to create bridges and highways that reliably serve their communities while simultaneously solving engineering challenges. RJ Watson is available to work with you to create a cost effective solution for your specific project.