Silicoflex Joint Sealing System

A high-quality, long-lasting, universal preformed silicone joint seal for bridges and highways.

Silicoflex Joint Sealing System is proudly manufactured in The United States of America.

Preformed Bridge and Highway Joint Seal

The Silicoflex Joint Sealing System was developed as a direct response to bridge owners asking for a higher quality, longer-lasting, more universal joint sealing system. The system is often used in bridge preservation activities as well as new construction and has been installed on thousands of bridges and highways worldwide.

Silicoflex Joint Sealing System

Silicoflex Joint Sealing System

Silicoflex Joint Sealing System

Silicoflex Joint Sealing System

Silicoflex Joint Sealing System

Silicoflex Joint Sealing System

Bond to new or existing steel, concrete or elastomeric concrete

The silicone expansion joint seal’s ability to bond to new or existing steel, concrete or elastomeric concrete joint headers makes it the most versatile system available. This bridge joint seal offers peace of mind, with an incredible track record of performance and longevity on existing installations that are over 20 years old on major highways across the US.

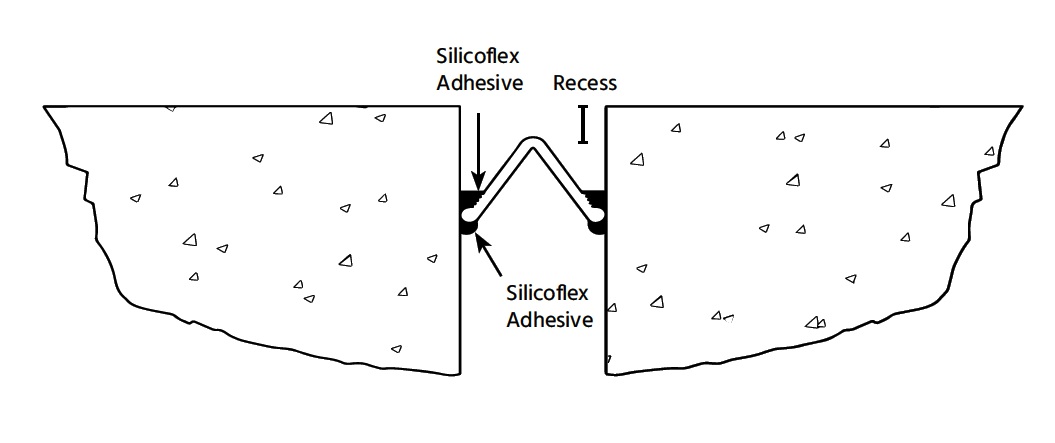

Silicoflex Expansion Joint System

The Silicoflex Joint Sealing System consists of an inverted V-shaped, preformed, extruded silicone rubber seal, installed with a single component silicone locking adhesive and a two-part primer. Two beads of silicone locking adhesive are used—one above and one below the silicone rubber seal—to ensure a tenacious, water-tight and continuous seal.

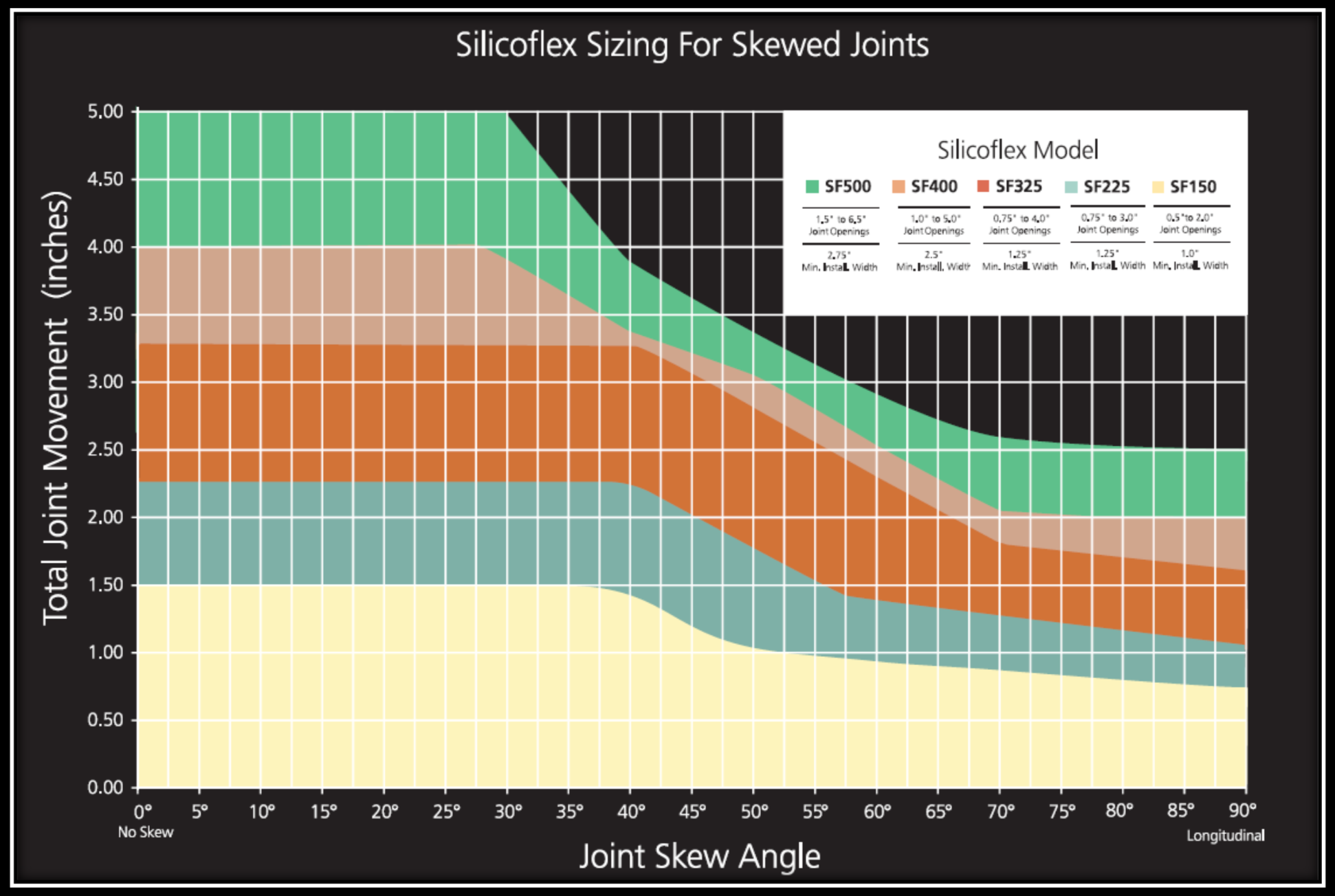

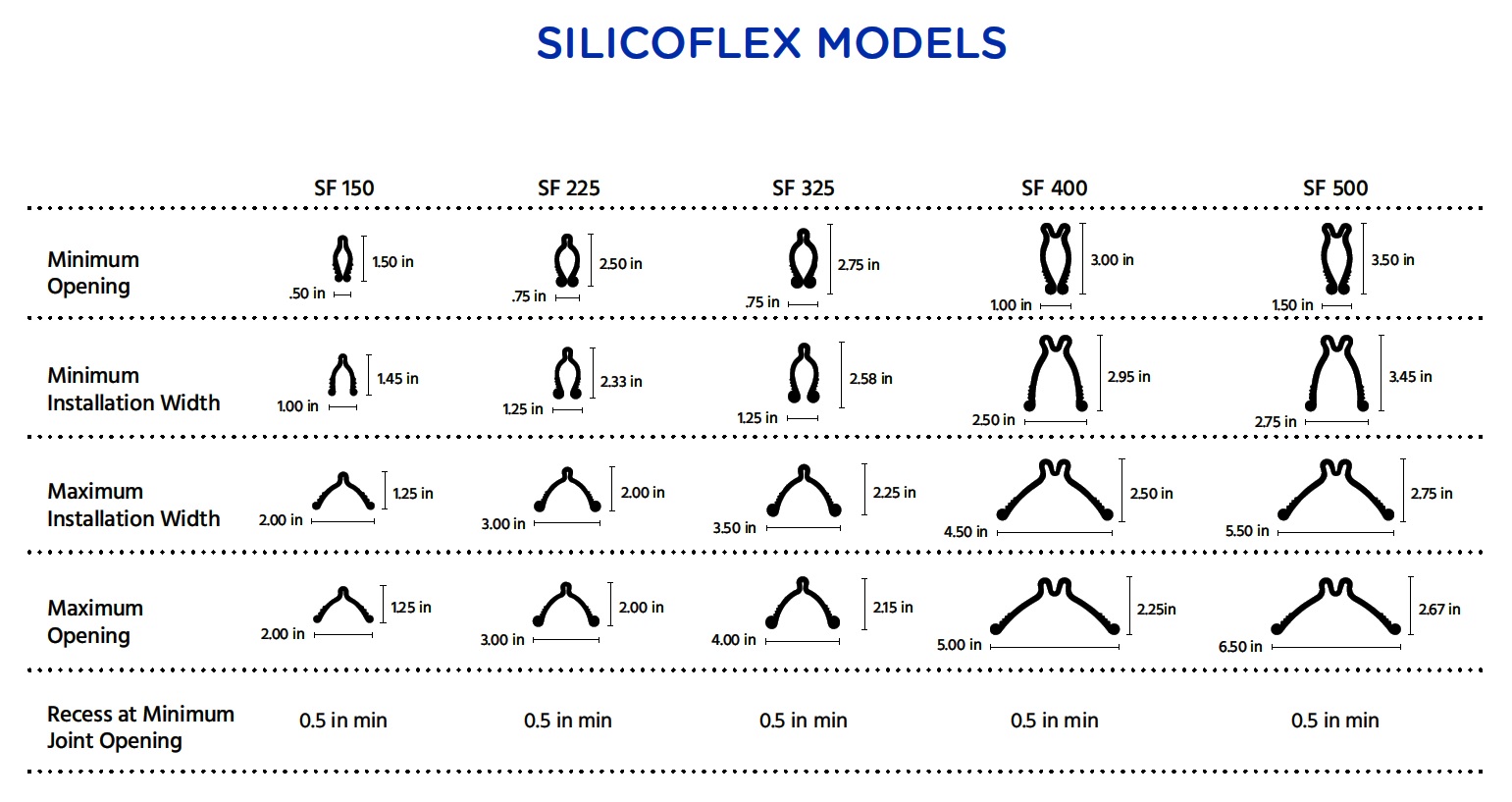

Joint Sealing System Options

By selecting one of five individual Silicoflex seals, any joint ranging from 0.5″ to 6.5″ can be sealed.

- SF150 Silicoflex: SF150 works on installations where the bridge expansion joint openings range from 0.5″ to 2.0″ and requires a minimum installation width of 1.0″.

- SF225 Silicoflex: SF225 works on installations where the bridge expansion joint openings range from 0.75″ to 3.0″ and requires a minimum installation width of 1.25″.

- SF325 Silicoflex: SF325 works on installations where the bridge expansion joint openings range from 0.75” to 4.0” and requires a minimum installation width of 1.25”.

- SF400 Silicoflex: SF400 works on installations where the bridge expansion joint openings range from 1.0″ to 5.0″ and requires a minimum installation width of 2.5″.

- SF500 Silicoflex: SF500 is ideal for situations where a bridge expansion joint may open greater than 4.5”.

- Armored System: In some instances, armoring the joint edges is preferable due to vehicular load.

Design and Test Your Joints

The experienced engineers at RJ Watson can help you find the right expansion joints for your project with our no cost, no obligation design and testing services.

Installing and Maintaining Silicoflex

After sandblasting (if necessary) and priming, the bridge joint seal installation time is about 15 to 20 minutes per lane. The lane can be reopened to traffic 30 to 60 minutes after installation. In the event of a puncture, Silicoflex can be easily repaired using our silicone-based locking adhesive. More severely damaged sections of expansion joint sealant can be removed and new pieces can be spliced in.

Featured Project

Carolina Bays Parkway – Myrtle Beach, SC

684 Linear Feet of Silicoflex 400 for 6 expansion joints on the Carolina Bays Parkway (Rte. 31) Extension, for a concrete bridge deck joint opening of 3.25” wide.

Bridge bearings and expansion joints for your structural needs

RJ Watson works with engineers, contractors and owners to create bridges and highways that reliably serve their communities while simultaneously solving engineering challenges. RJ Watson is available to work with you to create a cost effective solution for your specific project.